6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

Recommended

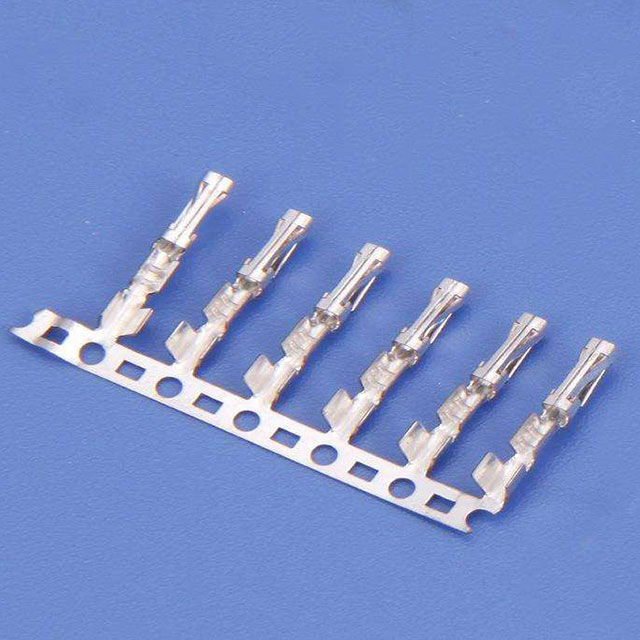

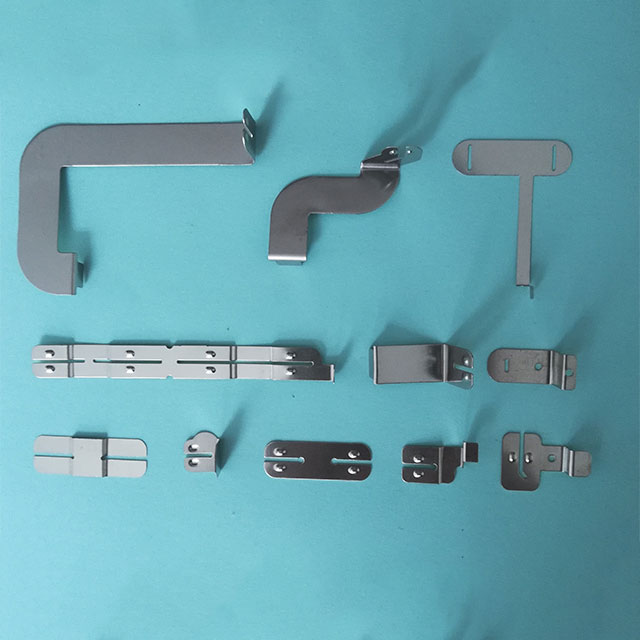

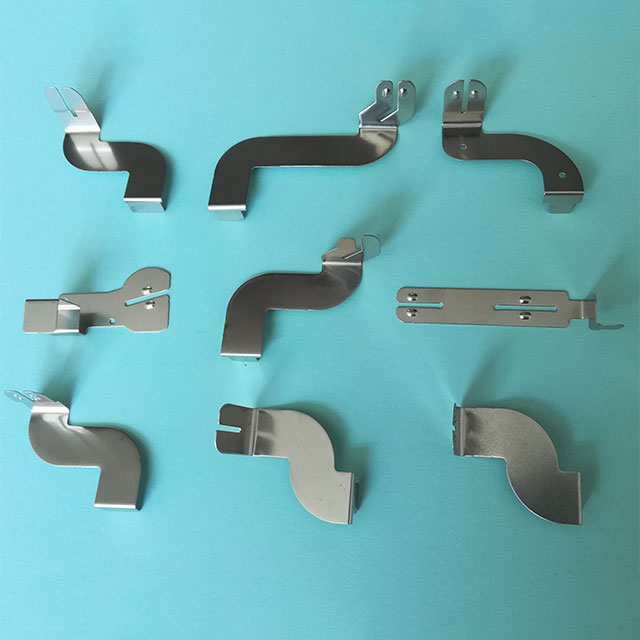

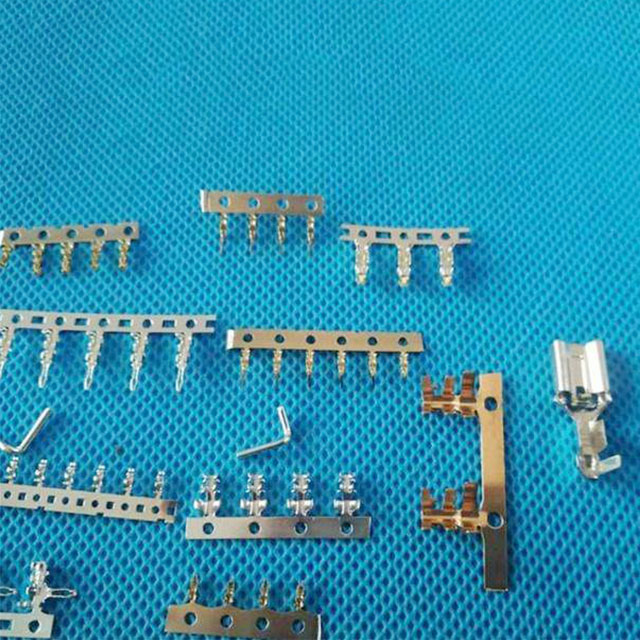

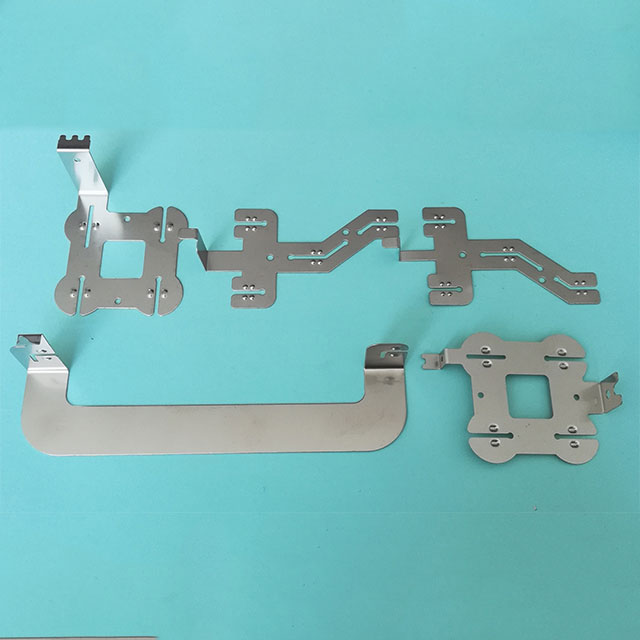

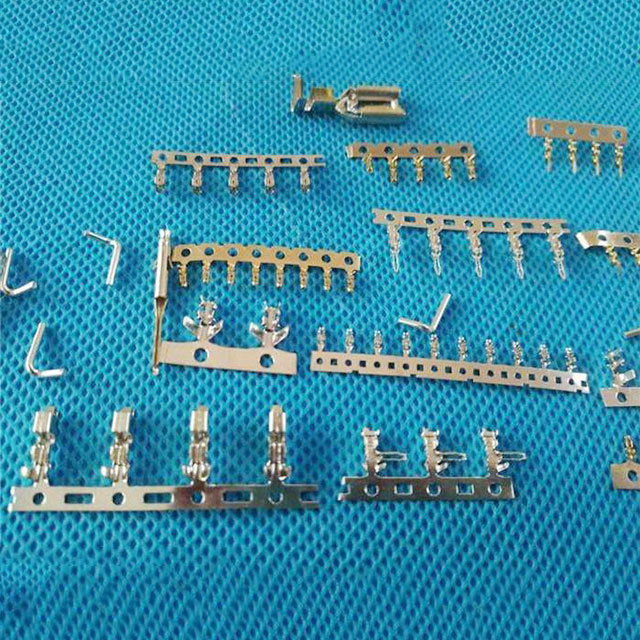

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

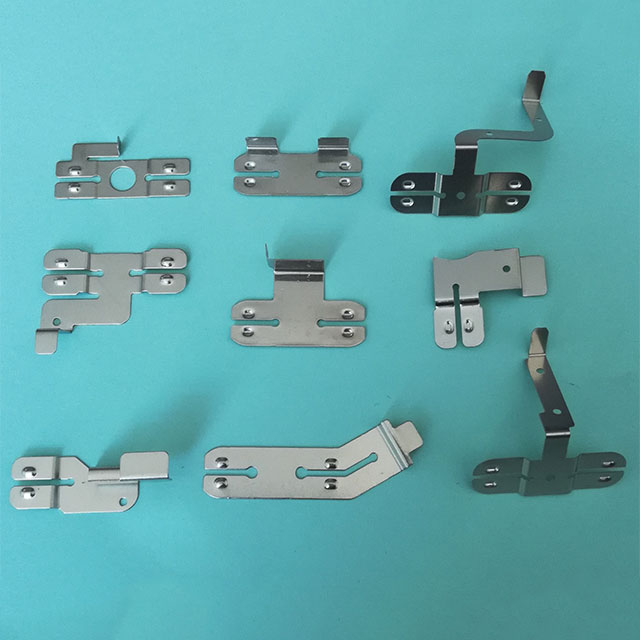

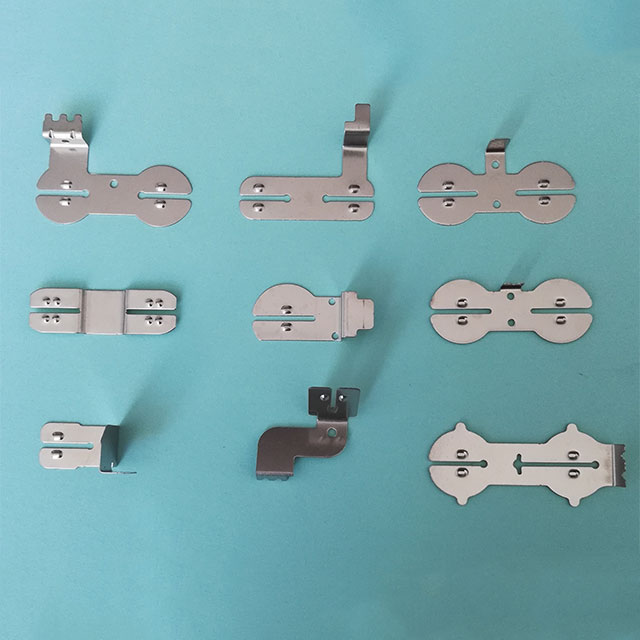

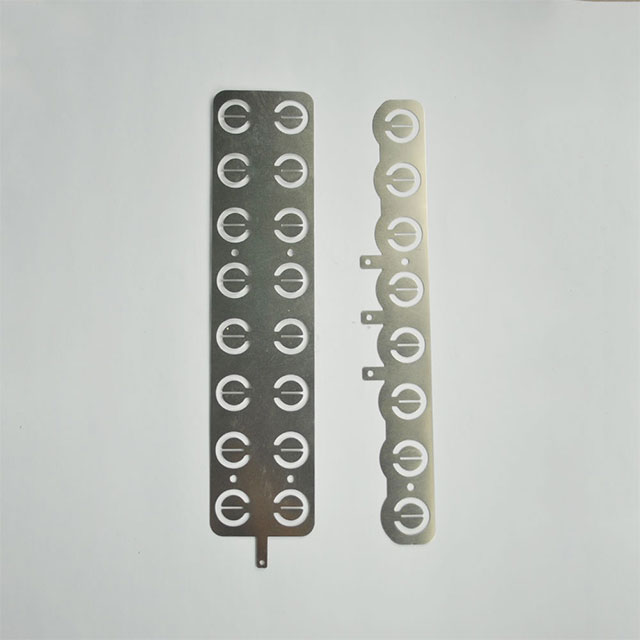

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

5G communication hardware 4

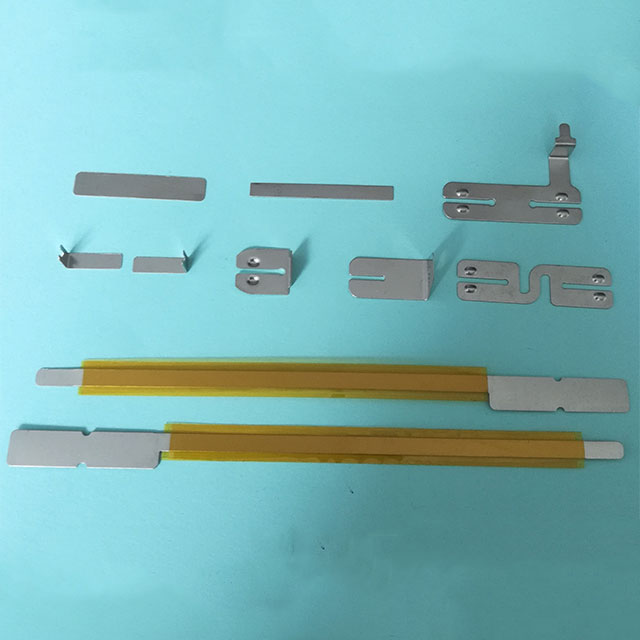

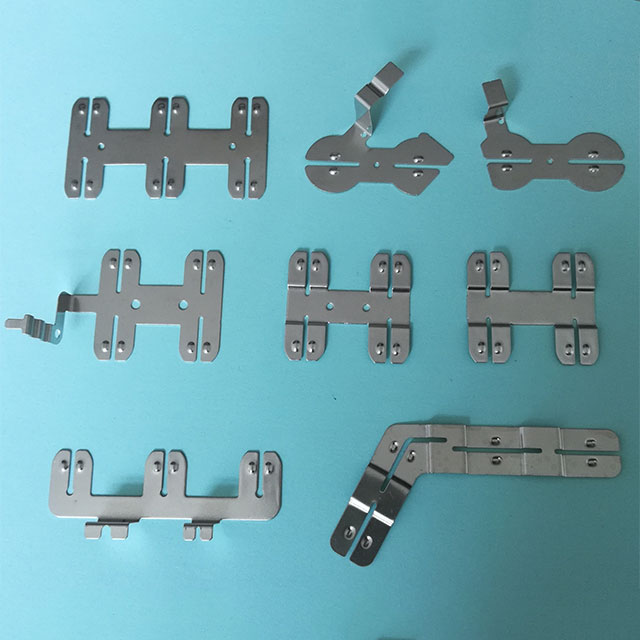

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Industry News HOME >> News >> Industry News

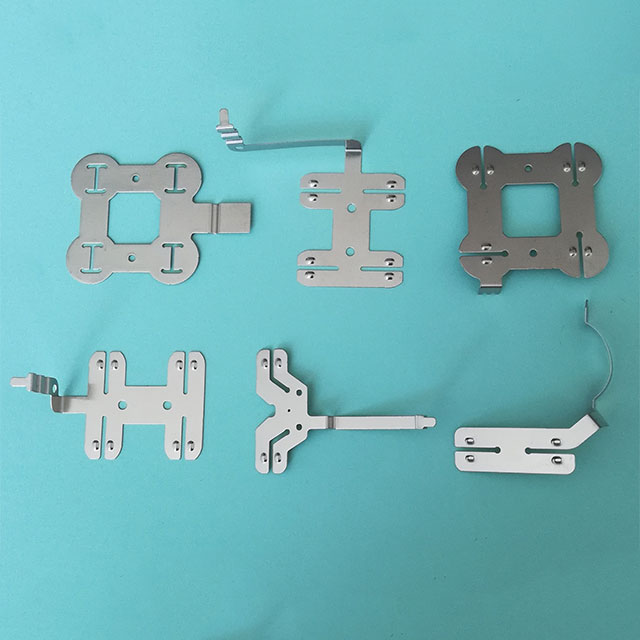

Several common processing procedures in metal stamping are: punching, punching the center hole, embossing, and embossing.

Punching is a stamping process that uses a die to separate part of the material or process parts from another part of the material, process (sequence) parts or waste. It is the general term for separation processes such as cutting, blanking, punching, punching, punching, slitting, chiseling, trimming, tongue cutting, cutting, and trimming.

Punching the center hole is a punching process in which a shallow concave center hole is formed on the surface of the process part, and the back material has no corresponding protrusions.

Embossing is a stamping process that forcibly squeezes out the material locally and forms shallow concave patterns, patterns, characters or symbols on the surface of the process parts. The back of the embossed surface has no protrusions corresponding to dimples.

Embossing is a metal stamping process in which a punch is used to squeeze into one side of the process part, forcing the material to flow into the opposite pit to form a protrusion.

Next page:Domestic hardware tool...

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

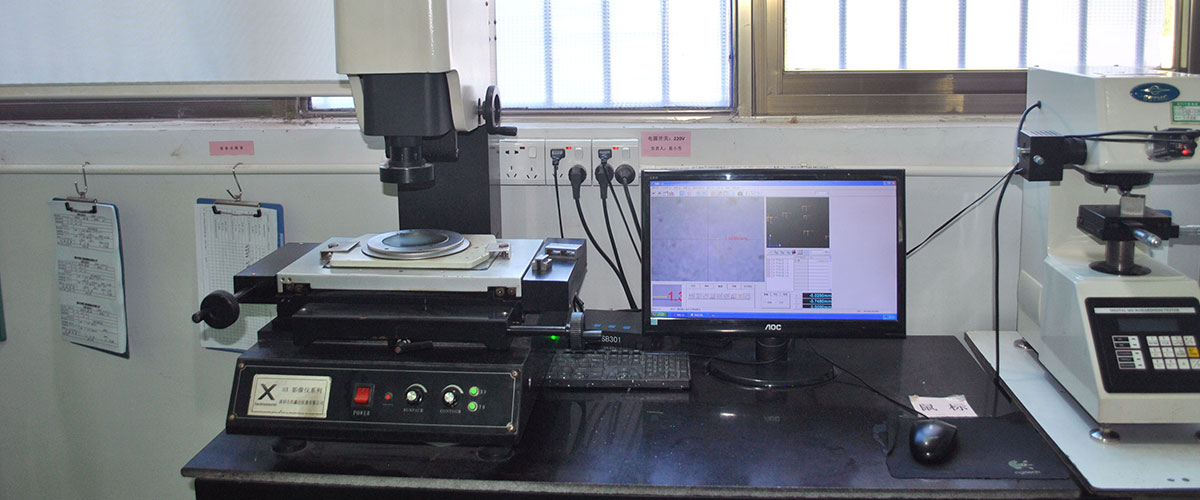

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products