6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

Recommended

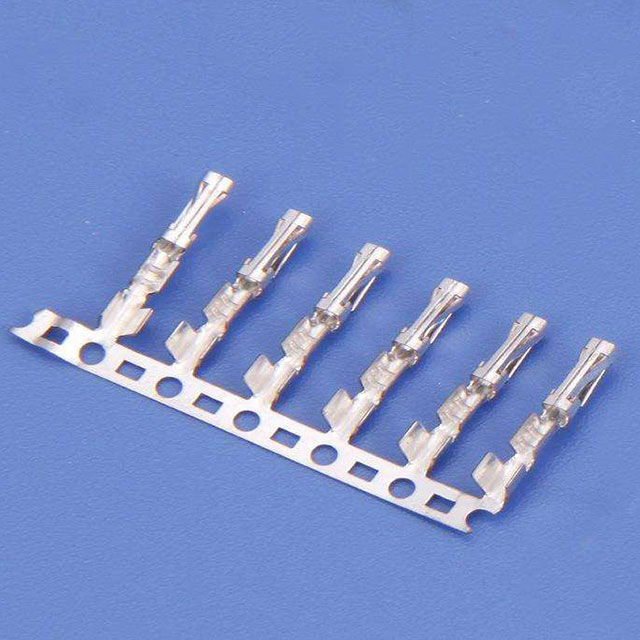

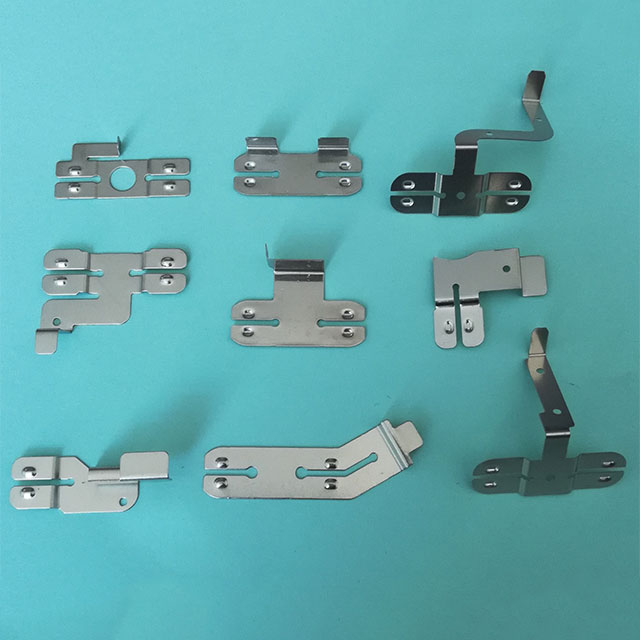

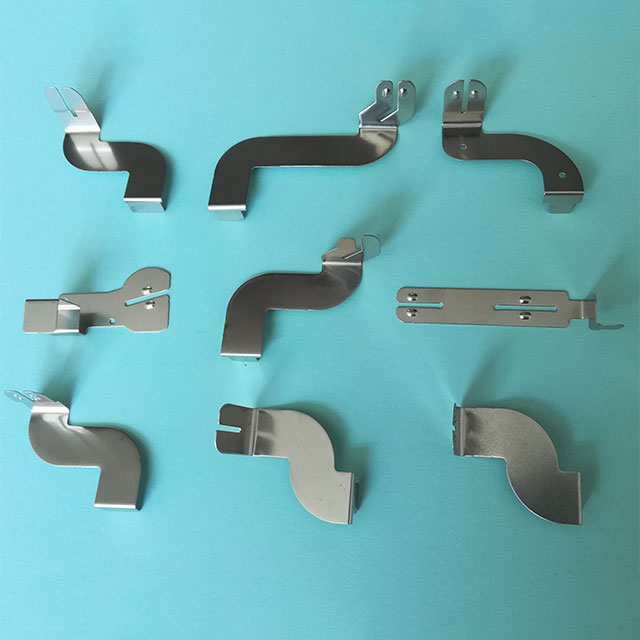

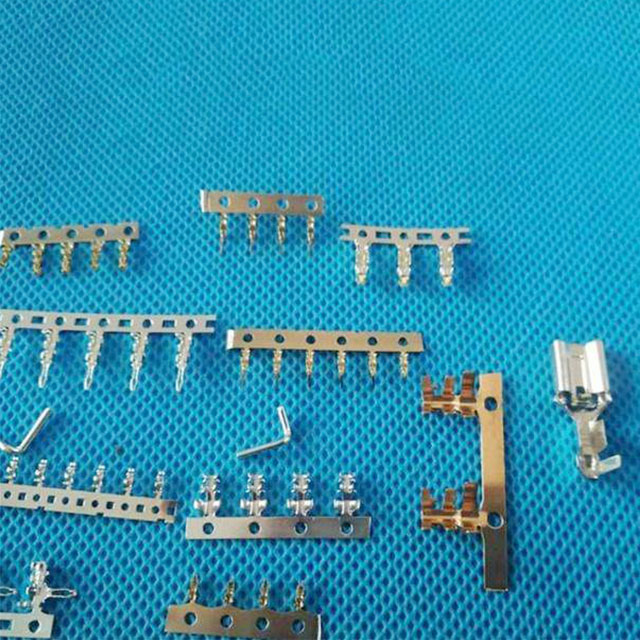

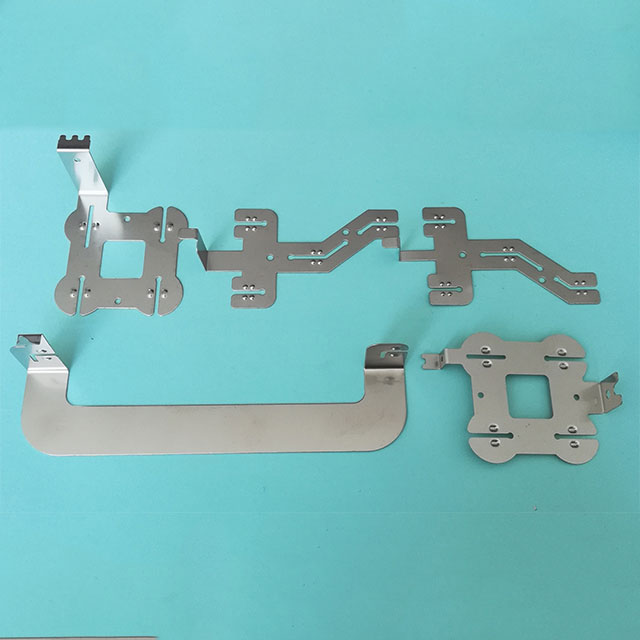

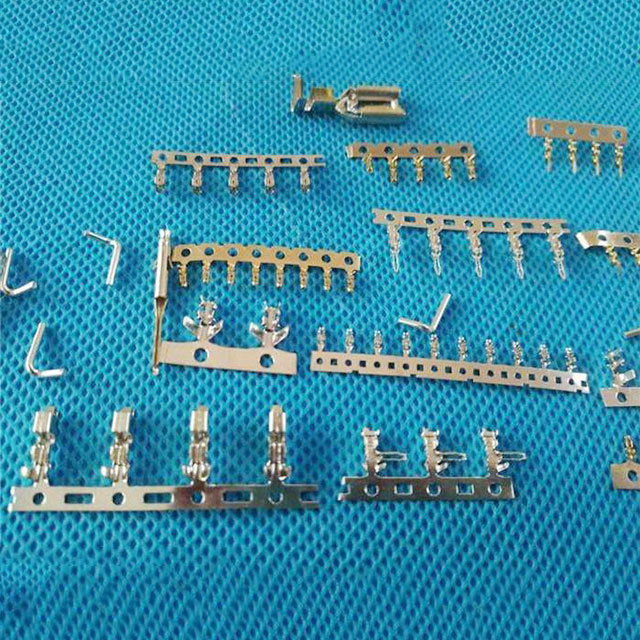

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

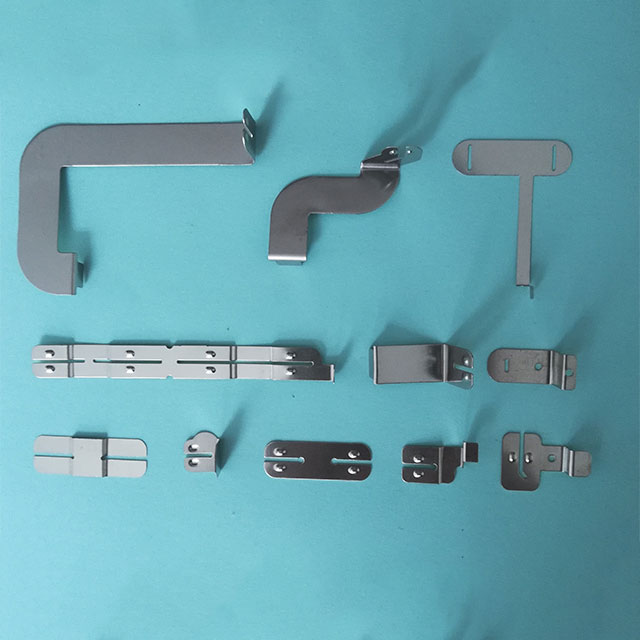

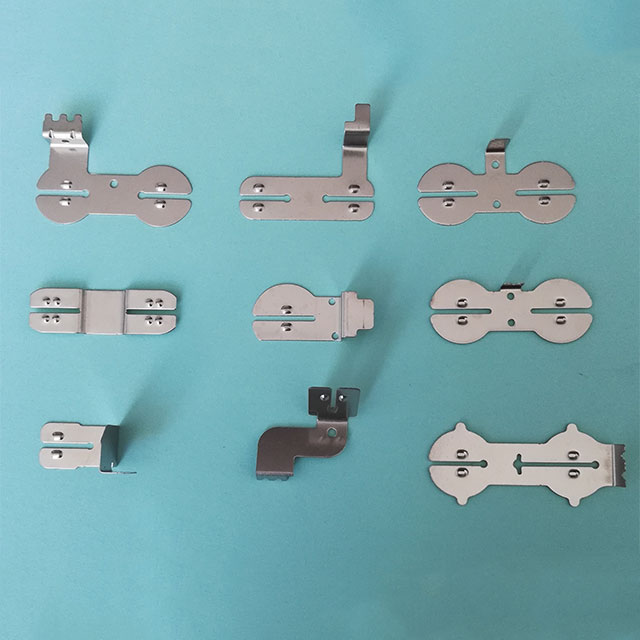

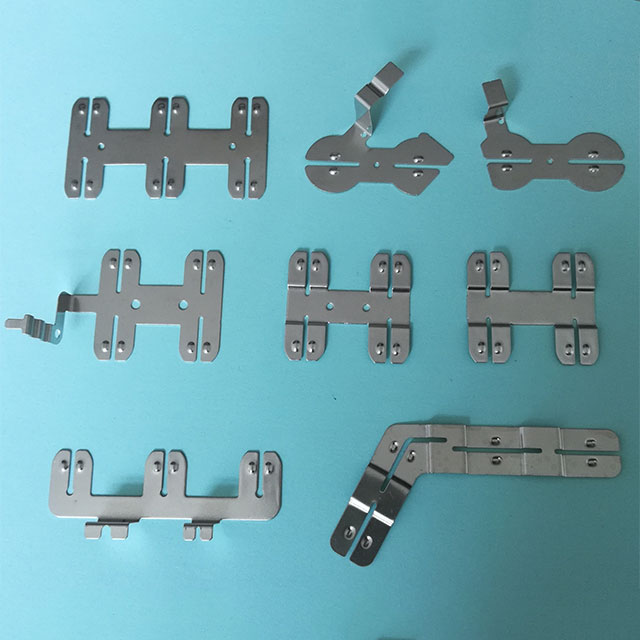

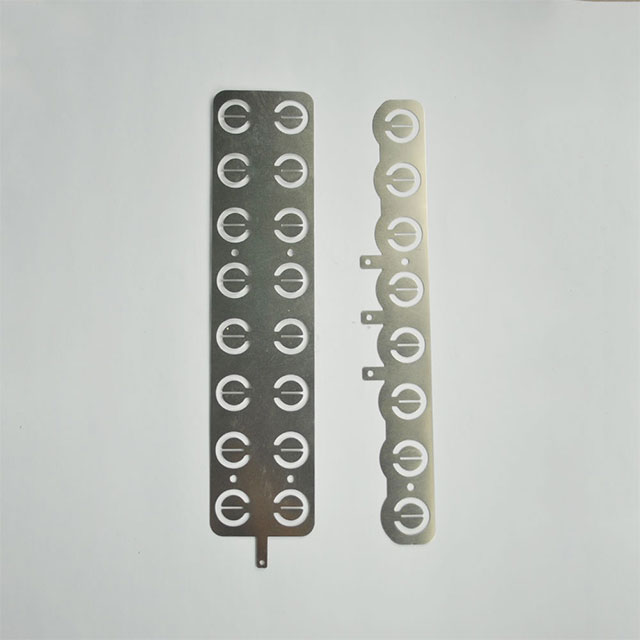

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

5G communication hardware 4

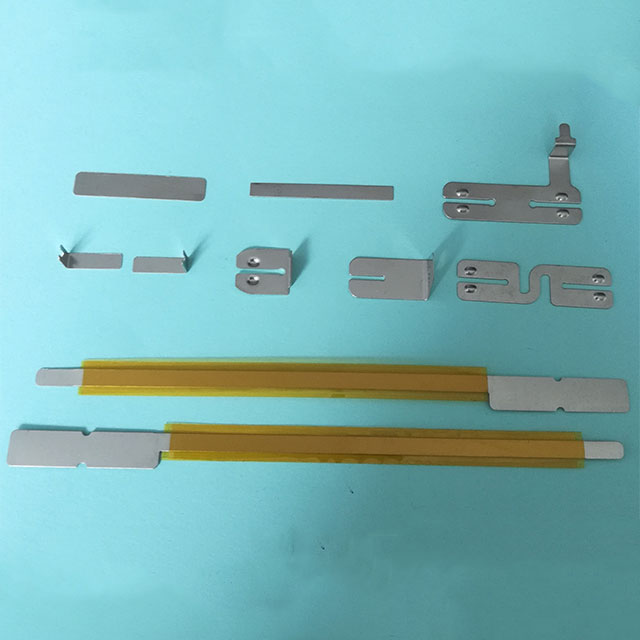

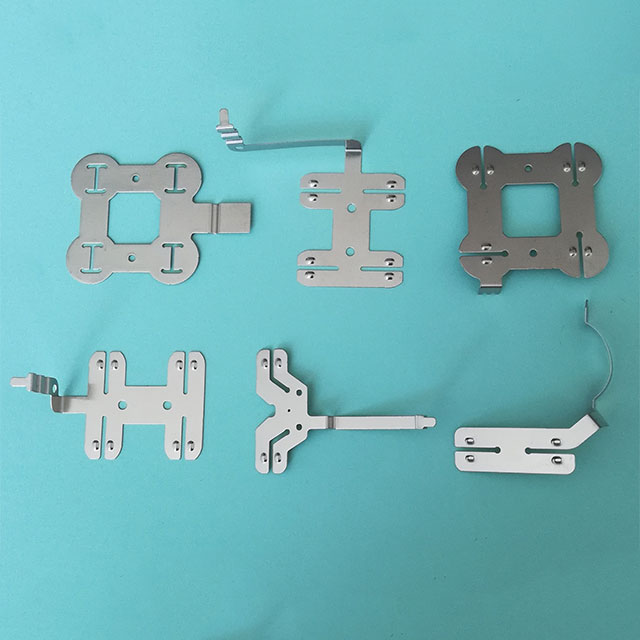

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Technical Article HOME >> News >> Technical Article

Appearance maintenance: clean inside and outside, no rust, no yellow robe. Spindle part: operating conditions of hydraulic fixtures and spindle operating conditions. Lubrication part: the amount of oil in each lubricating oil tank; each manual refueling point, refueling according to regulations, and rotating the oil filter. Wipe each part of the tape reader with gauze every month, and lubricate each operating point at least once every six months. Tailstock part: once a week, move the tailstock to clean the bottom surface and guide rails. Win the top once a week to clear the chase. Electrical part: check the three-color lights and switches. Check the position of each part of the control panel. Other parts: The hydraulic system has no oil dripping and heating. The cutting fluid system is working properly. The workpieces are arranged neatly. Clean around the punch to achieve cleanliness. Carefully fill in the shift record and other records.

The daily maintenance of the punch in the precision stamping processing plant can ensure the operation of the punch.

Good oxidation resistance, it will form a film to prevent oxidation when exposed to air; high temperature resistance can reach 1455 degrees Celsius. Plasticity and toughness are much stronger than copper.

Next page:What is the female charging...

How does the stamping factory maintain high-speed punches daily?

2020-08-15

What is the female charging port of the battery pack?

2020-08-15

Hardware shrapnel cleaning and precautions?

2020-08-15

What are the advantages of stamping?

2020-08-15

How to improve the production efficiency of stamping parts?

2020-08-15

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

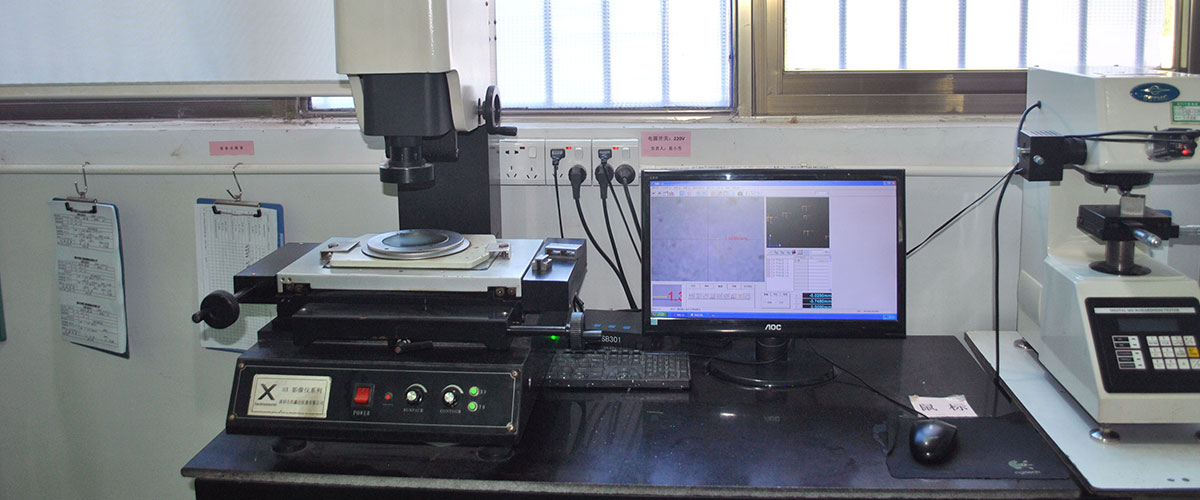

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products